APPLICATIONS

Engineered for use across critical pressure environments:

🔹 Pressure testing of open-end pipelines and vessels

🔹 Steam, oil, and gas lines

🔹 Fabrication shops and EPC projects

🔹 On-site maintenance and inspection work

Where sealing meets precision, OUT-MAX™ delivers.

KEY FEATURES & BENEFITS

🔹 Handles up to 15,000 PsiG (1034 BarG) safely and efficiently.

🔹 External grip-lock sealing system for a strong, secure grip

🔹 Prevents seal and pipe surface damage

🔹 Compact, robust body, built for industrial durability.

🔹 Reusable design cuts cost per test by up to 80%.

🔹 No welding, no grinding, no pipe modification required.

🔹 Custom sizes and seal materials available on request.

Result: faster installation, safer operation, and consistent results every time.

SPECIFICATIONS

|

Parameter |

Specification |

|

Size Range |

3/8″ – 48″ (DN10 – DN1200) |

|

Pressure Range |

Up to 15,000 PsiG (1034 BarG) |

|

Temperature Range |

−26 °C to +230 °C (−15 °F to +440 °F) |

|

Body Material |

Carbon Steel / Stainless Steel |

|

Seal Materials |

PU/NR/FKM |

|

Surface Finish |

Zinc-Plated, Polished, or Custom-Coated |

|

Connection Port |

¼″ NPT or Custom Options |

|

Customization |

Sizes, materials, and pressure ratings available on request |

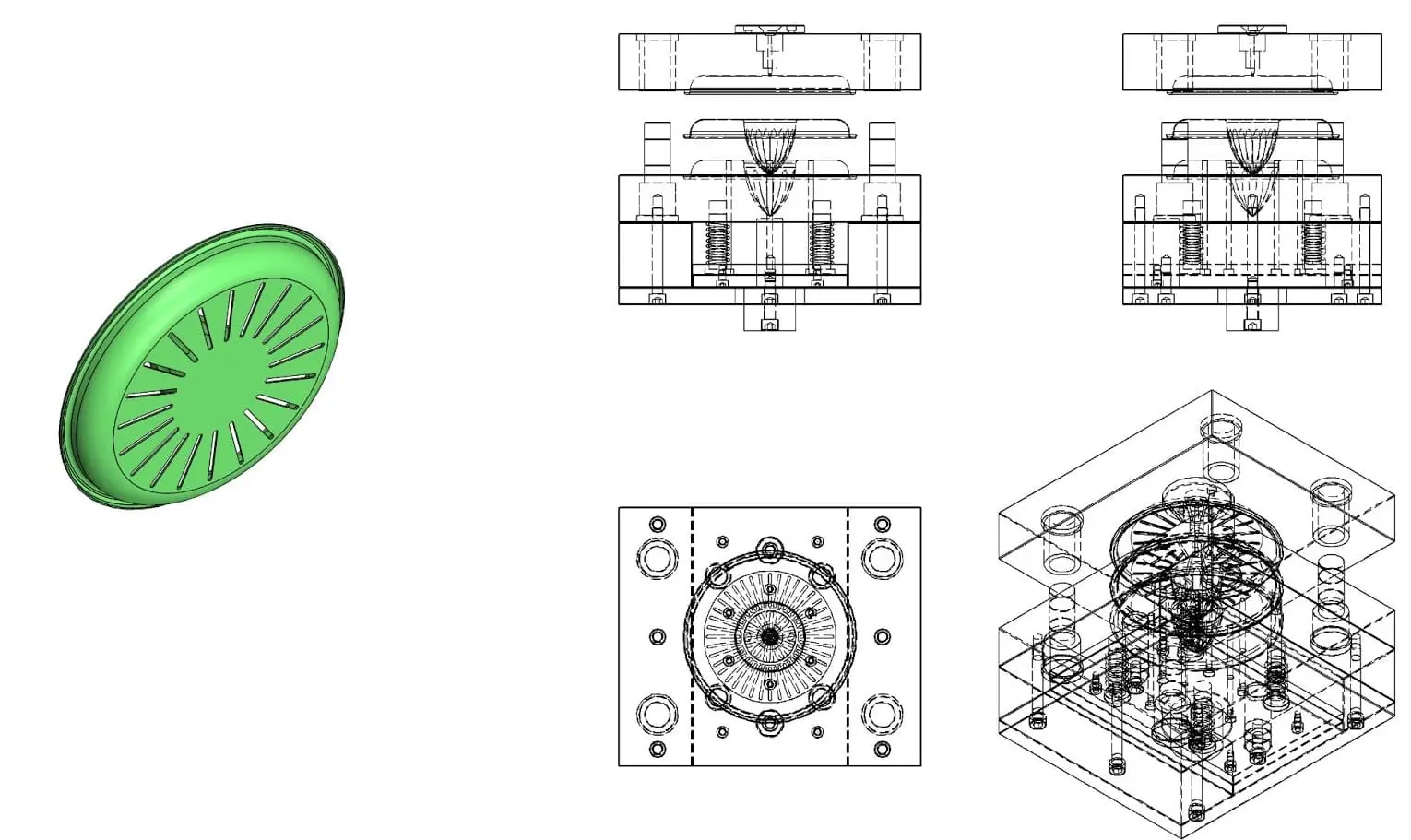

HOW IT WORKS

The OUT-MAX™ plug provides a secure external seal by locking around the pipe’s outer diameter. Installation is simple, fast, and requires no welding or internal access.

- Position the plug over the pipe’s open end.

- Tighten the grip-lock mechanism until firm contact is achieved.

- Connect the pressure line to the test port and fill with the desired test medium.

- Apply and hold pressure for the required test duration.

- Release pressure, vent the system, and remove the plug safely.

No welding. No cutting. No complications. just controlled pressure testing with total confidence.