APPLICATIONS

🔹 Offline or depressurized pipeline testing

🔹 Maintenance, inspection, and fabrication environments

🔹 Utility, process, and pipeline repair operations

🔹 Hydrostatic testing of weld joints and fittings

🔹 Pre-commissioning validation

🔹 Ideal for safe, repeatable tests in controlled conditions.

KEY FEATURES & BENEFITS

🔹 Dual-seal configuration isolates the weld zone precisely.

🔹 Compact and lightweight for easy handling and quick installation.

🔹 Uses minimal water volume for localized pressure tests (< 1 gallon).

🔹 Aluminum/steel hybrid construction — strong yet portable.

🔹 Ideal for depressurized or workshop testing.

🔹 Reduces downtime and testing costs compared to welded closures.

🔹 Custom sizes and seal materials available on request.

Result: precise testing, simplified setup, and engineered reliability for every weld.

SPECIFICATIONS

|

Parameter |

Specification |

|

Size Range |

¾″ – 48″ (DN20 – DN1200) |

|

Test Pressure Between Seals |

Up to 3700 PsiG (255 BarG) |

|

Upstream Pressure |

Up to 14.5 PsiG (1 BarG) |

|

Temperature Range |

−26 °C to +230 °C (−15 °F to +440 °F) |

|

Body Material |

Carbon Steel / Stainless Steel / Aluminum |

|

Seal Materials |

PU/NR/FKM |

|

Surface Finish |

Zinc-Plated, Polished, or Custom-Coated |

|

Connection Port |

¼″ NPT or Custom Options |

|

Customization |

Sizes and materials available upon request |

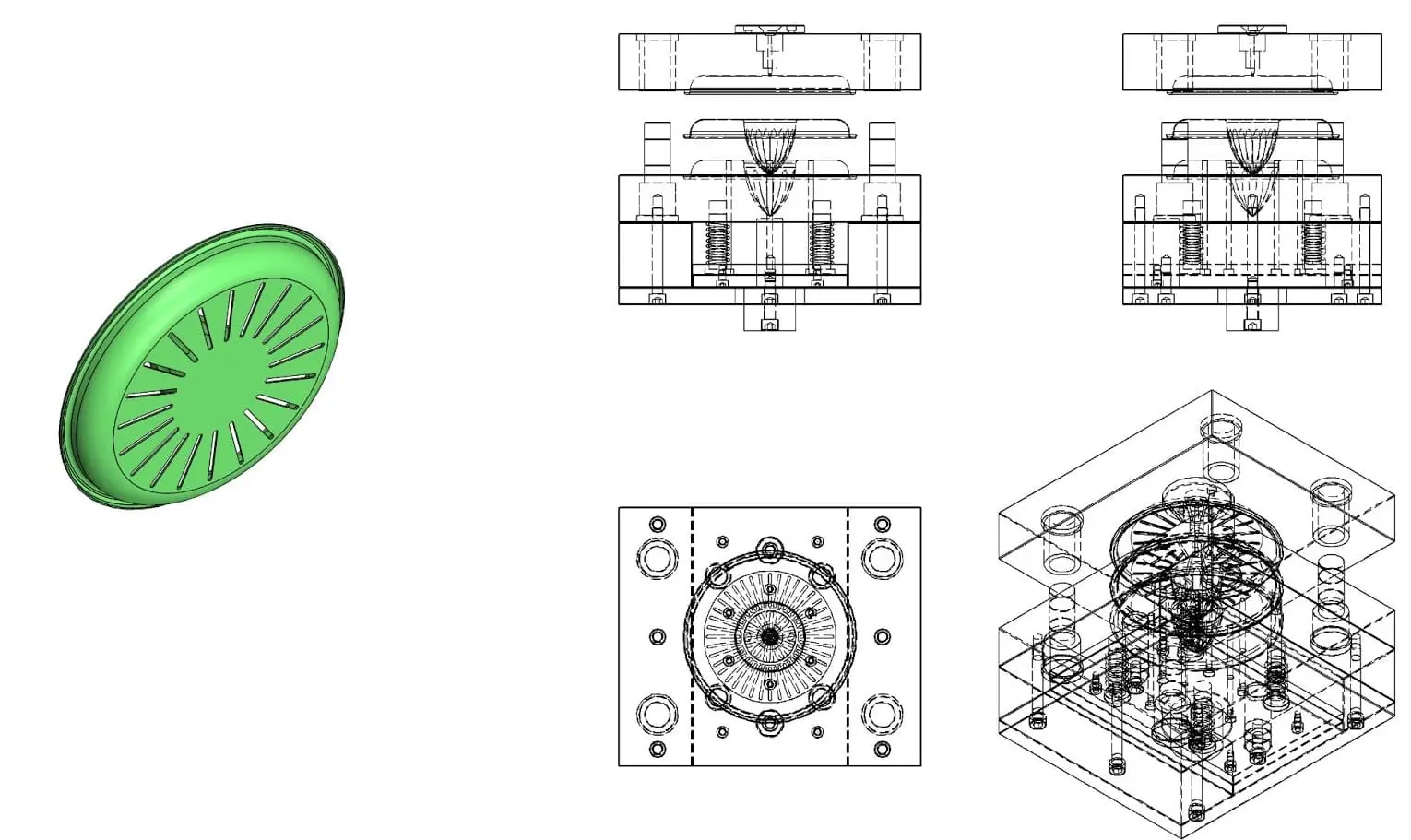

HOW IT WORKS

- Insert the DB-WELD™ plug into the pipe bore beyond the weld area.

- Tighten the compression nuts to expand the dual seals and create the isolation zone.

- Inject water through the test port to pressurize between the seals.

- Hold pressure for the required duration and monitor the test gauge.

- Release pressure and remove the plug. no cutting, no welding, no rework.

Fast installation, low-volume testing, and consistent performance every time.